Evolution Power Tools * | Evolution Power Tools 2 3/4 In. Dia. X 2 In. Depth Cyclone Premium Grade Cutter Cc275L Sale

$218.55 $83.36

Evolution Power Tools * | Evolution Power Tools 2 3/4 In. Dia. X 2 In. Depth Cyclone Premium Grade Cutter Cc275L Sale

Cyclone M2Al High-Speed Steel Annular Cutters:M2Al Cutters Have Been Developed As An Alternative To The More Common M2, M35, And M42 Cutters. M2Al Offers Many Advantages Over These Traditional Cutter Types. Tooth Hardness Is Optimized And Heat-Treated To 68Hrc To Maximize Cutter Performance. M2Al Cutters Also Include A Tapered Hardness From The Shank, Through The Cutter Body And To The Cutter Teeth. This Makes The Cutters More Resistant To The Torque Created While Cutting And Thus Prevent Breakage.

Included Pilot Pin: Evolution Recommends That All Annular Cutters Be Cooled Properly Throughout The Cut To Ensure Cutter Life Is Optimized. In Order To Accomplish This, An Included Pilot Pin Is Required So The Coolant Can Be Delivered Directly To The Cutting Surface. The Included Pilot Pin Is Yet Another Value-Added Feature That Makes Evolution Annular Cutters The Easy Choice For Industrial Drilling Applications.

Evolution Standard Geometry: Evolution Standard Geometry Is Sufficient For Most Drilling Applications. Manufactured Specifically To Maximize Hole Accuracy While Minimizing Cutter Vibration And Extending Annular Cutter Life.

Evolution Id Style Geometry: When Drilling Through Multiple Layers Of Material, Evolution Aos Id Style Cutters Are Recommended. Using This Custom Geometry Enhances Accuracy And Saves Time When Compared To The Alternative Method Of Stopping After Each Layer And Removing The Residual Slug. This Allows For A Single Ejection Of Slugs When Drilling Through Stacked Material.

Be the first to review “Evolution Power Tools * | Evolution Power Tools 2 3/4 In. Dia. X 2 In. Depth Cyclone Premium Grade Cutter Cc275L Sale” Cancel reply

Related products

Evolution Power Tools

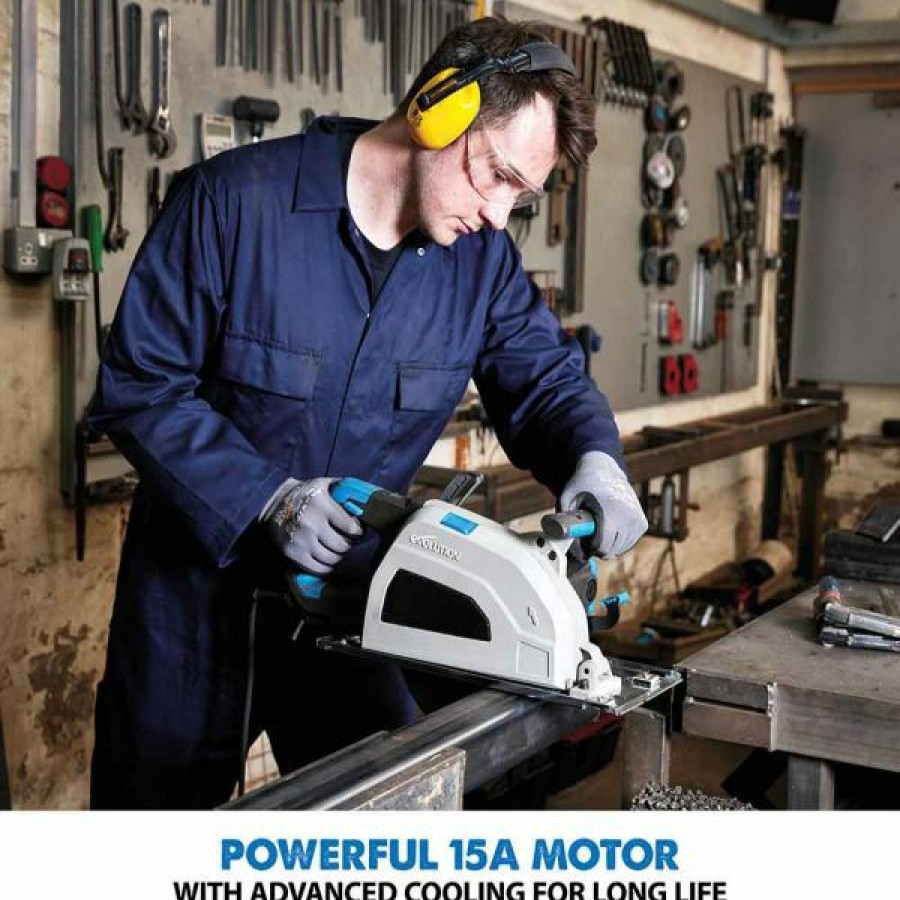

Evolution Power Tools * | Evolution 15 Inch Steel Cutting Chop Saw Eastwood Online

Evolution Power Tools

Evolution Power Tools * | Evolution 8 1/4 Steel Cutting Circular Saw S210Ccs Outlet

Evolution Power Tools

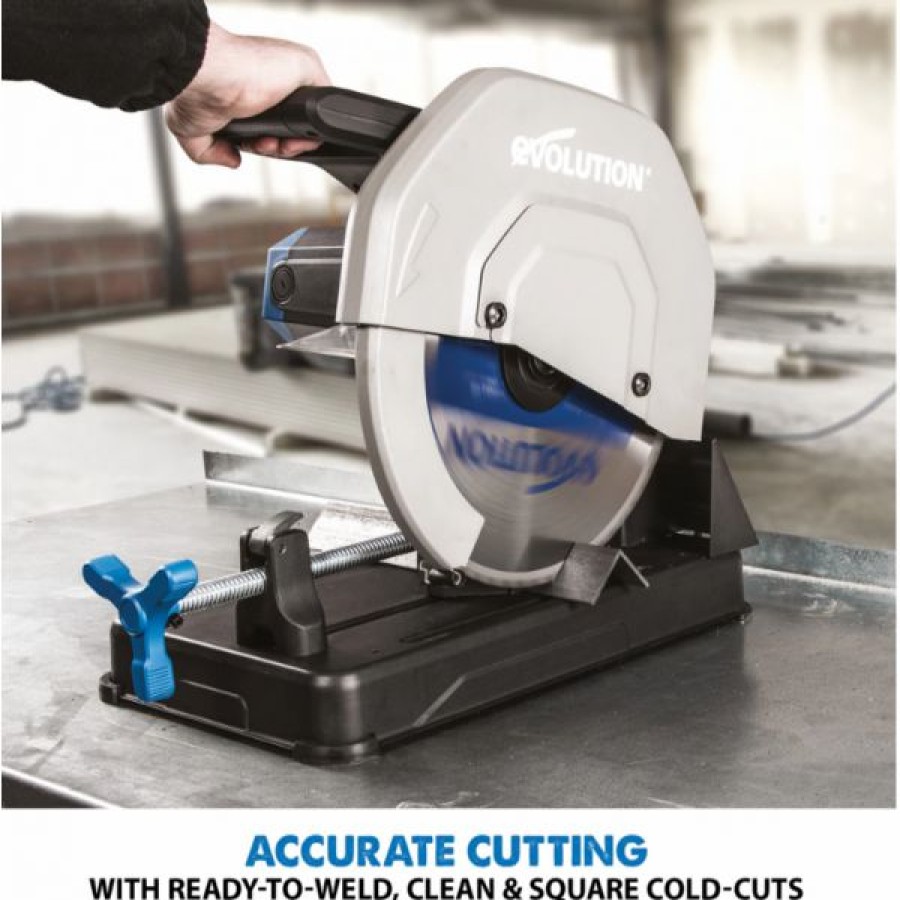

Evolution Power Tools * | Evolution 14 Inch Steel Cutting Chop Saw Sale

Evolution Power Tools

Evolution Power Tools

Evolution Power Tools

Evolution Power Tools

Evolution Power Tools

Reviews

There are no reviews yet.